Part Number: TE-1171

CM CAN Combo

Product Description

The CM CAN Combo is an active tap device that is used to capture traffic from conventional CAN buses, as well as CAN-FD, FlexRay, and RS-232. The traffic is captured without causing interference on the network and is delivered with a 40 ns resolution hardware time stamp. With a traffic shaping feature included, the logged output of multiple bus channels is steadily transferred to a data logger or test PC, eliminating bursts that might lead to a loss of data.

All logged data are provided in standard Ethernet frames via the open Technically Enhanced Capture Modules Protocol (TECMP). This protocol enables traceability of the source of traffic, on-the-source timestamp, packet counter, etc., making Ethernet the ideal logging network. The Capture Module CAN Combo emits messages timestamped with 40ns resolution, providing a fast and efficient solution supported by its extended Power Mode for car integration. Messages are sent within the PDUs of Ethernet MAC II frames via 100BASE-T1 (or Standard Ethernet).

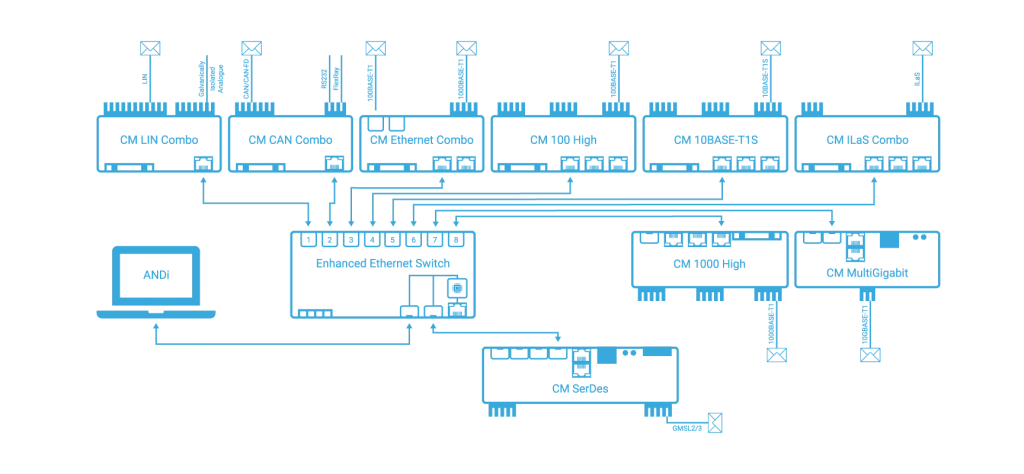

Several devices can be used to capture data on the same setup, as soon as more CAN ports are needed, or in case other IVN technologies have to be captured. The built-in synchronization using 802.1AS allows simultaneous use of the Capture Module CAN Combo together with the other IVN2Eth Capture Modules. This also enables cascading of multiple Capture Modules via the Enhanced Ethernet Switch.

The device can easily be configured on a browser website, via the built-in webserver of the Capture Module CAN Combo. Additionally, it includes a rotary switch for the manual configuration of its IP addresses.

The Capture Module CAN Combo includes a Startup Buffer and High-Speed Startup feature (<200 ms), so the initial startup information of the system is instantly captured. This way, the device can record all the important information emitted by the network, without missing any message in the communication between devices.

Technica Engineering´s Capture Module is a highly innovative and unique traffic-capturing solution, with exclusive characteristics adapted to the current technological requirements in the Automotive field.

Our new generation of active tap devices is developed to fulfill the most critical requirements in contemporary automotive ECU development, which is the reason why our products are used by the premium OEMs in the field. The variety of additional features makes the Capture Module CAN Combo a great choice for general-purpose testing.

Technical data

FACTS

- 1 × MQS connector for 6 × CAN /CAN-FD channels

- 1 × MQS connector for

- 1 × FlexRay (Channel A) channel

- 2 × RS-232/TTL serial interface

- 1 × Rotary switch

- 1 × MQS connector with

- 1 × FPGA port for logging and time synchronization

- 1 × Host port for configuration only

- 1 × 1000BASE-T Standard Ethernet RJ-45 port for logging and time synchronization

- 6 × Status LEDs (2 of them at the RJ-45 port)

- Optimized for automotive and automotive-like use-cases

- Robust galvanized sheet steel with black powder coated housing

- High voltage range: 12 to 24 volt DC

- Power consumption: 4,7 to 7 Watt

- Size: 129 × 120 (134) × 32 mm

FEATURES

- Captures traffic from CAN buses, CAN-FD, FlexRay, and RS-232

- Easy configuration via web server or dedicated UDP frames

- Network Time Synchronization supports several standards (ANVU gPTP / 802.1AS, PTPv2) – allowing the user to synchronize multiple Capture Module variants and other devices

- Source Timestamping with 40 ns resolution

- High-speed Startup (<200ms)

- Startup Buffer

- Output Traffic Shaping

- CAN/CAN-FD/FlexRay Transmission (with a license)

- Rotary switch for manual configuration of the device IP address (Gbit, RJ-45)

- Extended power mode for car integration

- Wake-up/Sleep functionality (also via CAN/-FD)

- Status LEDs

- Use of the open Technically Enhanced Capture Module Protocol (TECMP), which is royalty-free and provides timestamping, source information, etc. (natively supported in Wireshark (v3.4). GPL C libraries for conversion to PCAPNG available at https://github.com/Technica-Engineering)

Use case

Downloads

Further information below